Forest image: Joe - Pixabay

Lignin is arguably the most abundant component of biomass that most people have never heard of. That may be about to change.

Many people are familiar with its biochemical cousin cellulose, a byproduct of paper and wood milling. But the same processes produce 50 million tons of lignin annually, industry experts estimate. Once distilled, 98 percent of the inky liquid is burned to produce electricity.

Scientists have been working to find more efficient and sustainable approaches to transform this naturally occurring polymer for use as a cleaner and greener building block to develop next generation materials.

Boston College chemists have developed an approach that uses light to transform lignin into sustainable plastics, the team reported recently in the journal ACS Central Science.

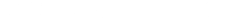

Schematic illustration of different strategies to process lignocellulose. (a) Two industrial routes of processing woodmeal, namely, the pulp industry or the lignin oil industry. (b) Mechanisms of hydrogen-atom transfer to break the β-O-4 motif, which is abundant in native lignin. (c) Overview of our strategy to first depolymerize native lignin and then repolymerize the resulting oligomers using dynamic covalent cross-linkers. Credit: ACS Central Science (2022).

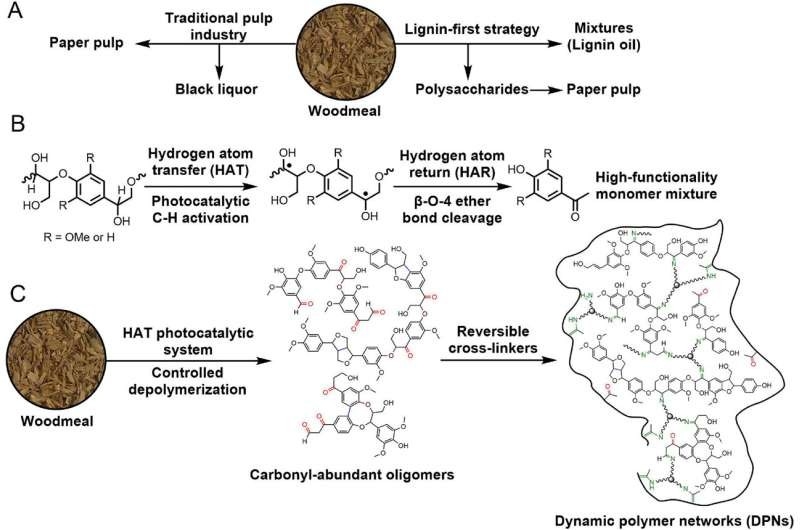

Report co-author, associate professor of chemistry Jia Niu (Lee Pellegrini)

“We developed a catalyst that can selectively break down specific chemical bonds in lignin when it is exposed to light, such that the lignin is converted into intermediate-sized, soluble molecules called oligomers,” said Boston College Assistant Professor of Chemistry Jia Niu, a co-author of the study.

The team then converted the oligomers into sustainable plastics by reacting with a molecular glue called crosslinkers, according to the report. Because of the unique chemical structures of the oligomers created by the catalyst, the plastics made in this way can be chemically broken down back into the oligomers, and reformed from the oligomers and the crosslinker.

The findings advance a potential strategy for the waste-free system of polymer manufacture and re-use known as the circular plastic economy, said report co-author Dunwei Wang, Boston College’s Margaret A. and Thomas A. Vanderslice Chair in Chemistry.

Vanderslice Chair in Chemistry and report co-author Dunwei Wang (Lee Pellegrini)

“Transitioning from petroleum to biomass as the feedstock for energy and material production can help to address some of the most important challenges our society is facing, such as climate change and plastic pollution,” said Wang. “New methods that can make advanced materials from lignin will greatly improve the efficiency for biomass utilization.”

Wang and Niu, who share an interest in making sustainable materials, Ěýarrived at the project based on Wang’s expertise using photocatalysis to drive chemical transformations and Niu’s work making recyclable polymers.

“The pleasant surprise was the level of controls we were able to exert in decomposing lignin, which is a biopolymer that is notorious for its difficulty to break down,” said Wang. “Such a level of control paves the way for downstream applications.”

The research team aims to further develop the novel method that converts lignin into sustainable plastics that can be readily recycled through chemical means.

In addition to Niu and Wang, additional co-authors of the report– titled “” – include graduate students Hongyang Wang and Gavin Giardino and former post-doctoral researchers Rong Chen and Cangjie Yang.

Ed Hayward | University Communications | April 2023